There is a sweetness to some of the most toothy and tasty recipes that come to mind. Bitter, Sweet, Sour, and Salty are the three main tastes that the human tongue senses. Yet we prefer to have a sweet taste as we have grown from primates consuming fruits from trees and getting a sweet taste that has been created.

Our love of sugar and sugar products continues to develop, and we also avoid caring about the calories found in sugar. And it became possible to eat sweet food. But not to consume this with the advent of scientific progress. Read on to what aspartame is made of, as well as how aspartame is made.

What is Aspartame?

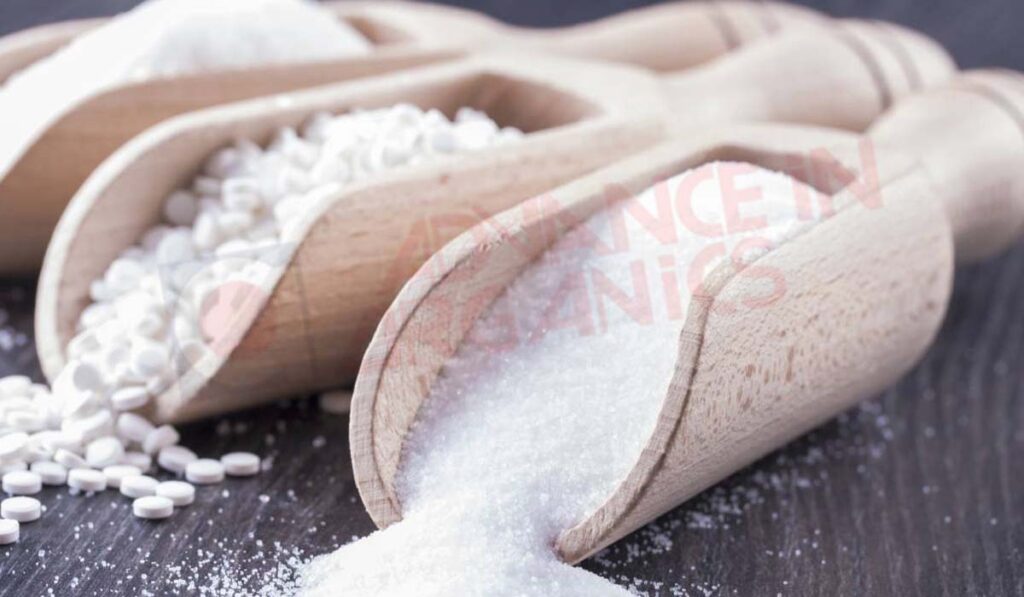

A first-generation sweetener is an aspartame (ASP). It is a chemical made from two amino acids, L-aspartic acid, and L-phenylalanine methyl ester. Aspartame is not stable in heat and loses its integrity at a pH below 3.

As a baking sweetening agent, it is harmful and is the most controversial artificial high-intensity sweetener. EFSA analyzed ASP in an investigation conducted in March 2009 and found no genotoxic or carcinogenic potential.

NutraSweet, Equivalent, SC-18862, Canderel, Methyl Aspartylphenylalanine, Methyl Ester, Aspartylphenylalanine, or AminoSweet, which is the latest brand, can be found on the market under different names.

What is Aspartame Made Of?

The processes make it of oxidation and synthesis. Yeast helps to produce the starting amino acids required for aspartame formation. That is achieved with the help of particular forms of bacteria capable of producing such amino acids. The L-aspartic acid and L-phenylalanine-generating glutamicum bacteria are inserted into a tube containing the nutritional requirements for their development. Once they have spread in the test tube, they transfer to a storage process.

The seed tank fills with things that bacteria, including hot water and carbohydrate foods such as cane molasses, glucose, or sucrose, need to grow. There are also carbon factors, such as acetic acid, alcohol, hydrocarbons, and nitrogen sources, such as liquid ammonia or iodine.

It provides agitators and exhaust air that help the bacterial population to succeed. The last process for the bacteria is the yeast tank, a bigger model of the seed tank. After that, they provide growth and generate large amounts of amino acids.

When sufficient amino acid production, the yeast tank mixture transfers out to start coating, it is removed through an oxide column and processed. Next is the crystallizing tank to remove these amino acids. They are split up and dried via a crystal separator after oxidation.